Fiber Laser Marking Machine

INTRODUCTION

Fiber laser marking machine is the most accepted technology among the laser marking systems due to its versatility, minimal maintenance and nil requirement of consumables. Unlike Co2, it uses optical fiber doped with rare earth element as a laser source and can mark with much more intensity comparatively. It provides best industrial solution for product identification and traceability.

Why choose fiber laser?

Laser marking is permanent, faster, accurate and now a well-known marking and engraving solution for the metal and non metals. Marking lasers work with short peak power laser pulses. Pulse power, duration, and frequency determine the available energy, which influences the interaction between the laser beam and the material. Galvo guide the laser beam at high speeds across the work piece. Each laser pulse produces a pixel.

Why Laser Marking?

- Permanent & indelible marking process.

- Non-contact type – doesn't produce stress or change physical properties of materials.

- Clean and Safe process –Chemical-proof, water-proof, oil, grease & fuel-proof.

- Internationally Accepted as Quality Marking Standard.

- No pre or post processing – Can be done on finished products.

- Automated – can be integrated with existing production or packaging line. Controlled by Computer.

- Flexible – mark texts, alphanumeric, logos, bar codes, graphics, images, 2D data matrix code etc.

- Harmness – doesn't affect quality of marking.

- Least set up time – no tooling and jigs required.

- No consumables.

- Enhances the aesthetical & monetary value of products.

- Counterfeit & Forgery prevention, product tracking & identification and so on.

APPLICATION

Fiber laser marking/engraving machine is suitable for various metals (SS, MS, aluminum, gold, silver, etc), alloy, metallic oxide materials and some non-metallicmaterials(silicon wafer, ceramics, plastic, rubber, epoxy resin, ABS, printing ink, plating,spraying, and coating film, etc

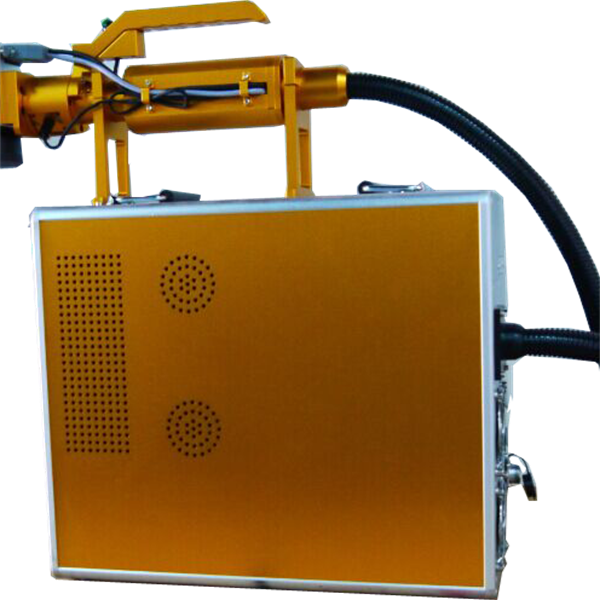

DETAILS

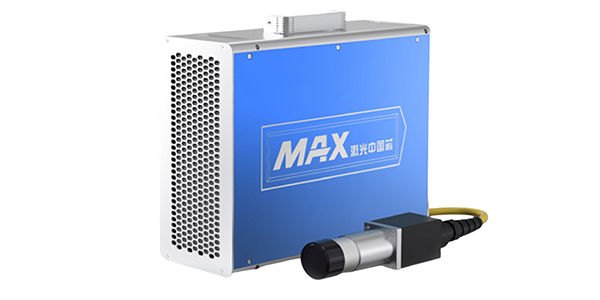

MAX laser source, low failure rate, good quality, life time 100000 hours, RAYCUS, JPT and IPG source for option

JCZ control system and EZCAD software with stable performance and high reliability, the machine including computer, before delivery, software and parameter are set.

SINO galvo equipped with micro motor, fast speed, high precision and long life, with double red light pointer help customer make focus quickly and easily.

Field lens with good light perception, uniform light, small size, suitable for harsh environments

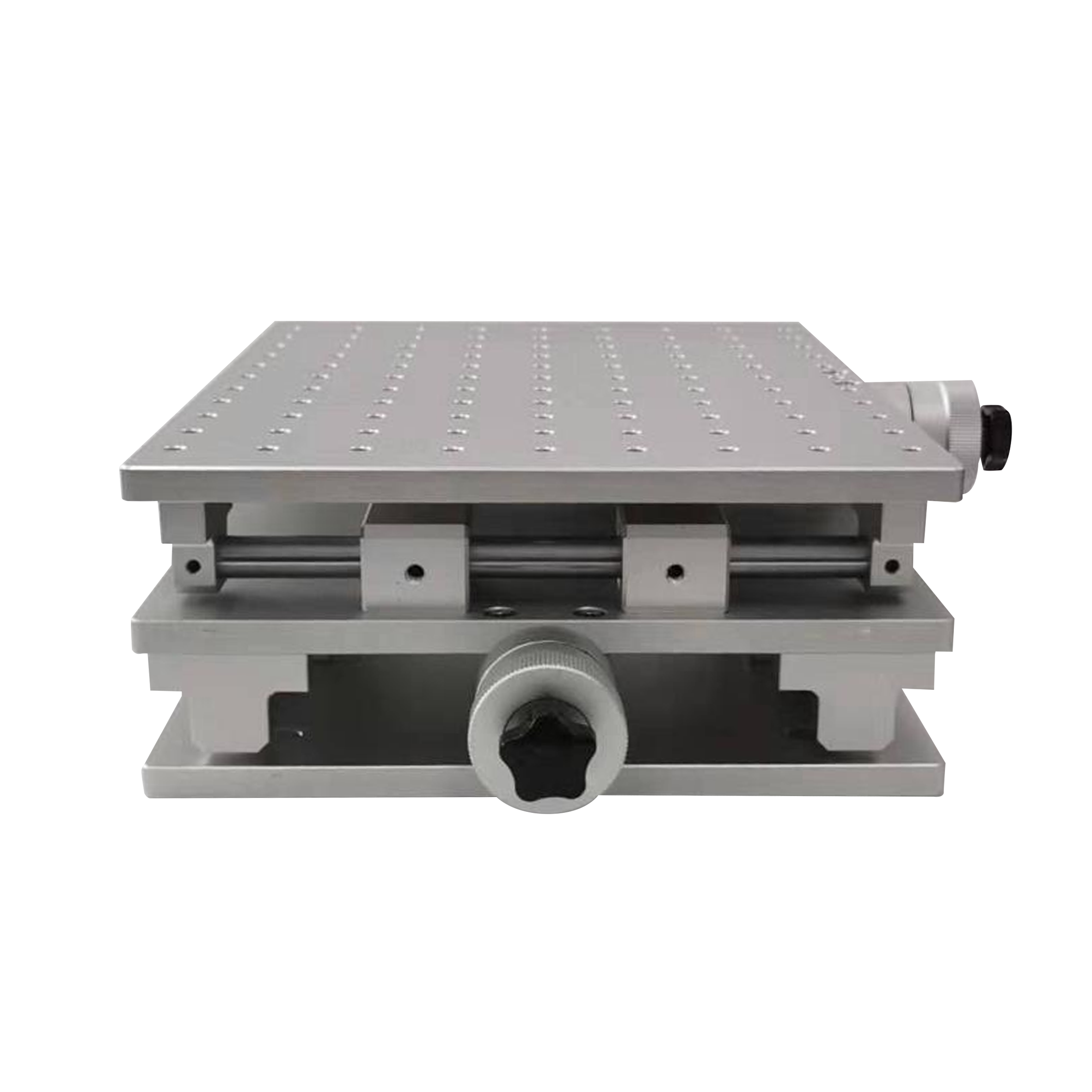

Working table has standard positioning holes, convenient and fast positioning, can be adjusted to meet different needs, improve work efficiency

Lift shaft using excellent materials, effective and stable, high positioning accuracy, firmness

PARAMETER

|

Laser Power:20W/30W/50W/100W |

Marking Area:110 x 110mm /200 x200mm/300 x300mm |

|

Controller: JCZ |

Software: EZCad |

|

Laser Device: MAX Option: Raycus /IPG/JPT |

Laser Wavelength:1064nm |

|

M2/Beam quality M2: <1.2 |

Min. Line Width: 0.01mm (0.0004") |

|

Min. Letter: 0.2mm (0.008") |

Power supply: 220V / 50Hz / 1kVA |

|

Cooling Method: Air cooling |

Engraving Speed:7000mm / s (275IPS) |

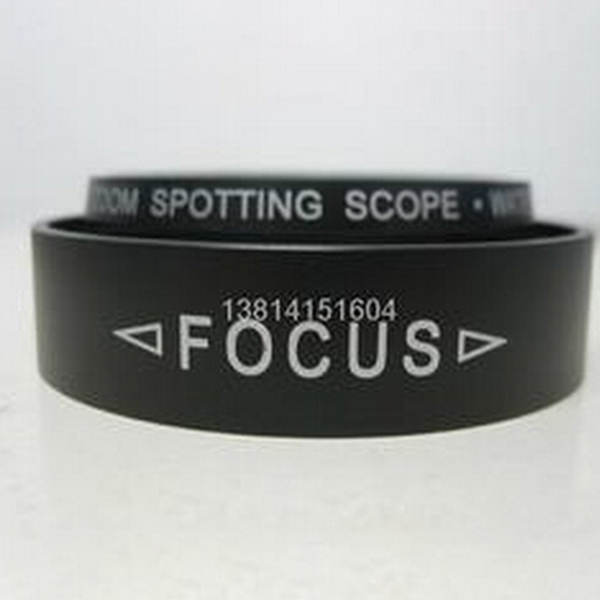

SAMPLE

OPTION

Rotary

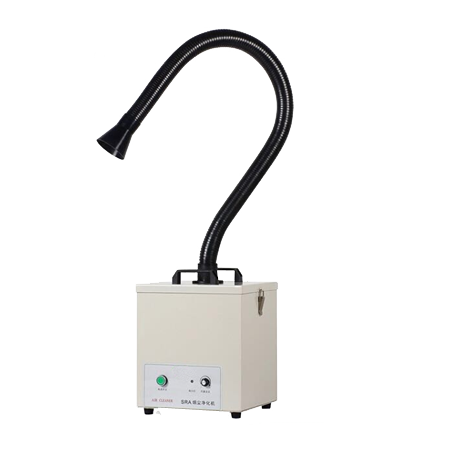

Dust collector

2D/3D table

OTHER MODELS

Customized service is available according to your products and marking requirement.