Fiber Laser Cutting Machine Master JZ1530

PARAMETER

| Model | JZ1530 |

| Laser power | 1000---6000w |

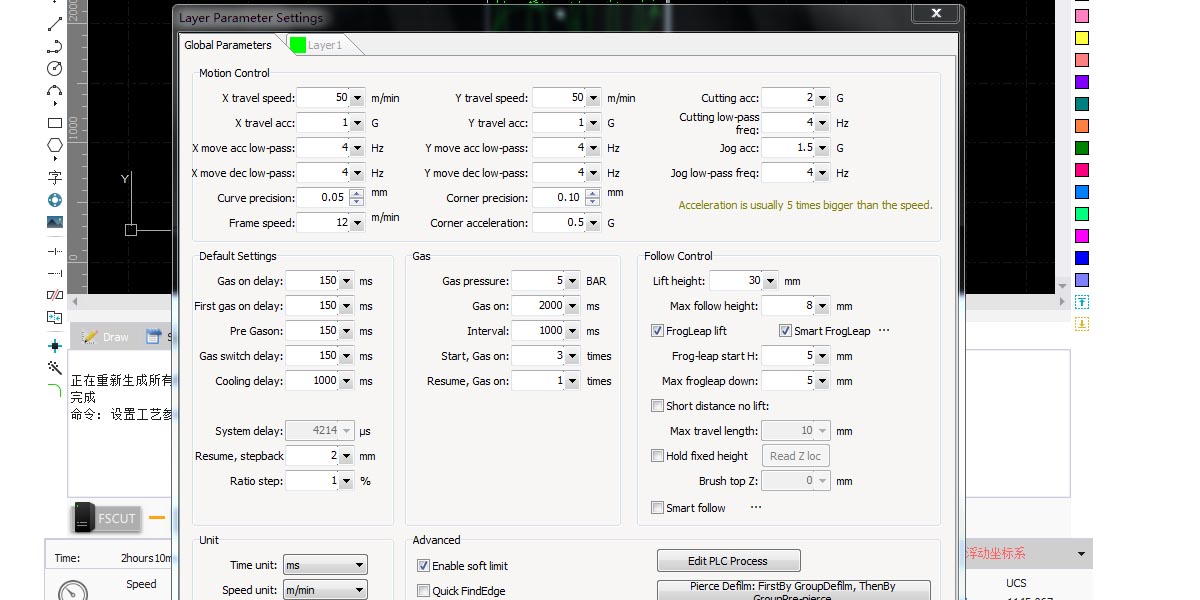

| CNC Control system | Cypcut 2000E |

| Laser source | Raycus/Max/Reci |

| Laser head | Raytool BM110 |

| Drive | Taiwan DELTA servo motors |

| Reducer | Taiwan Faston |

| Transmission | Taiwan SHAC guide rail, Germany Lean rack |

| Laser lens | Raytool |

| Proportional valve | Japan SMC |

| Solenoid valve | Japan SMC |

| Max cutting acceleration | 2G |

| Resolution ratio | 0.025mm |

| Re-position precision | ±0.02mm |

| Power requirement | 220/380V, 50/60HZ |

| Applicable material | stainless steel, carbon steel, galvanized sheet, iron, aluminum, brass, copper |

| Auxiliary gas | Pure air or Oxygen or Nitrogen |

| Graphic supported | DXF、DWG、JPGE、PCX、AI、TIFF、PLT、CDR、BMP |

| Computer with original laser software | WIFI function available |

APPLICATION

Application Materials: Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

2.Application Industries: JZ Fiber Laser Cutting Machines are widely used in manufacturing Billboard, Advertising, Signs, Signage, Metal Letters, LED Letters, Kitchen Ware, Advertising Letters, Sheet Metal Processing, Metals Components and Parts, Ironware, Chassis, Racks & Cabinets Processing, Metal Crafts, Metal Art Ware, Elevator Panel Cutting, Hardware, Auto Parts, Glasses Frame, Electronic Parts, Nameplates, etc.ensure that it can operate possible during the laser cutting process.

DETAILS

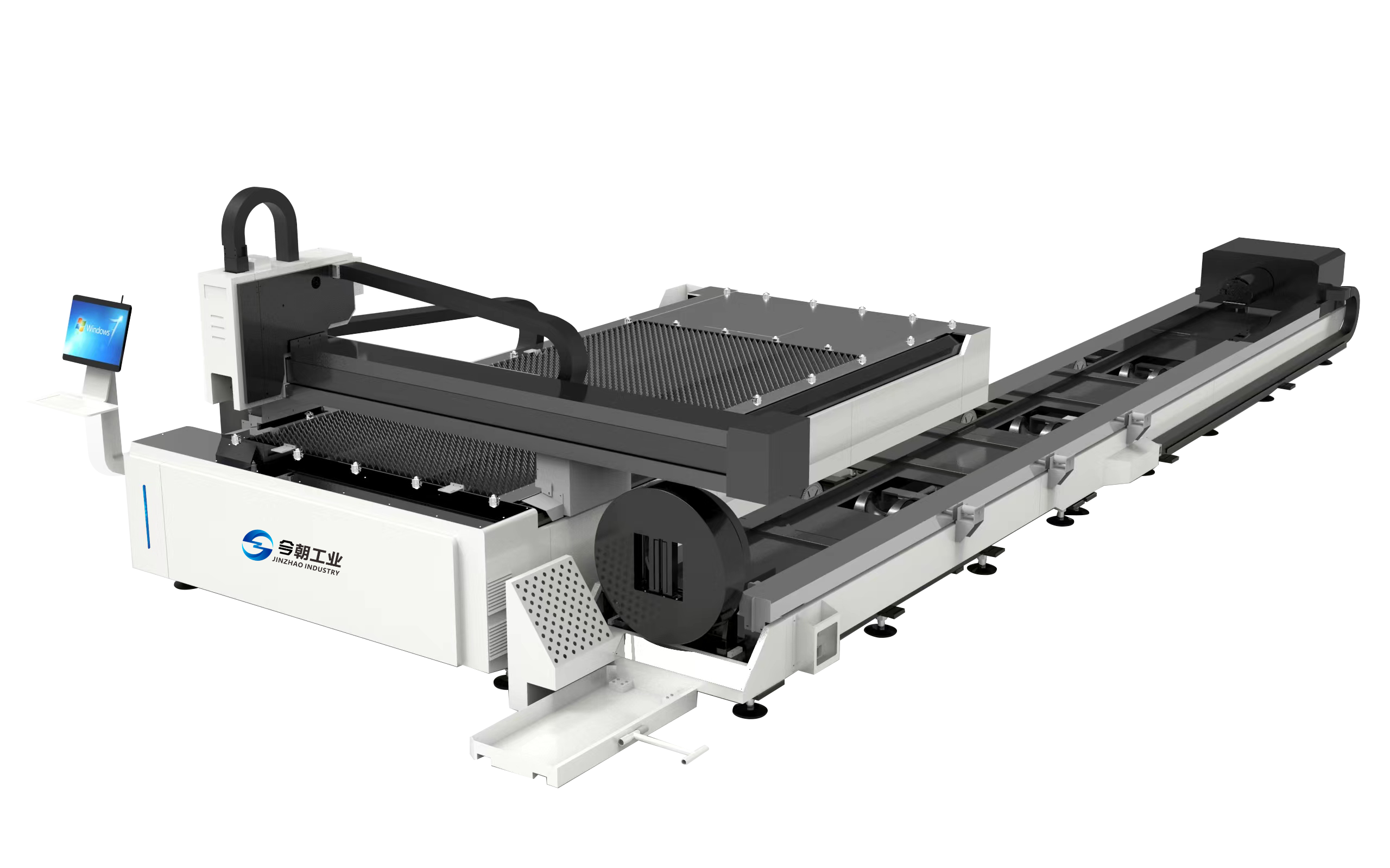

8mm thick and heavy machine bed, more stable when machine cutting at high speed, machine body no shake at all.

Machine bed is milled by large CNC planer type milling machine, the bed is on the same level, conducive to high accuracy.

Collimator and dial gauge used to ensure machine high precision.

2G Max cutting acceleration, take short time from low-speed cutting to high-speed cutting, cuts corners or turning points more smoothly.

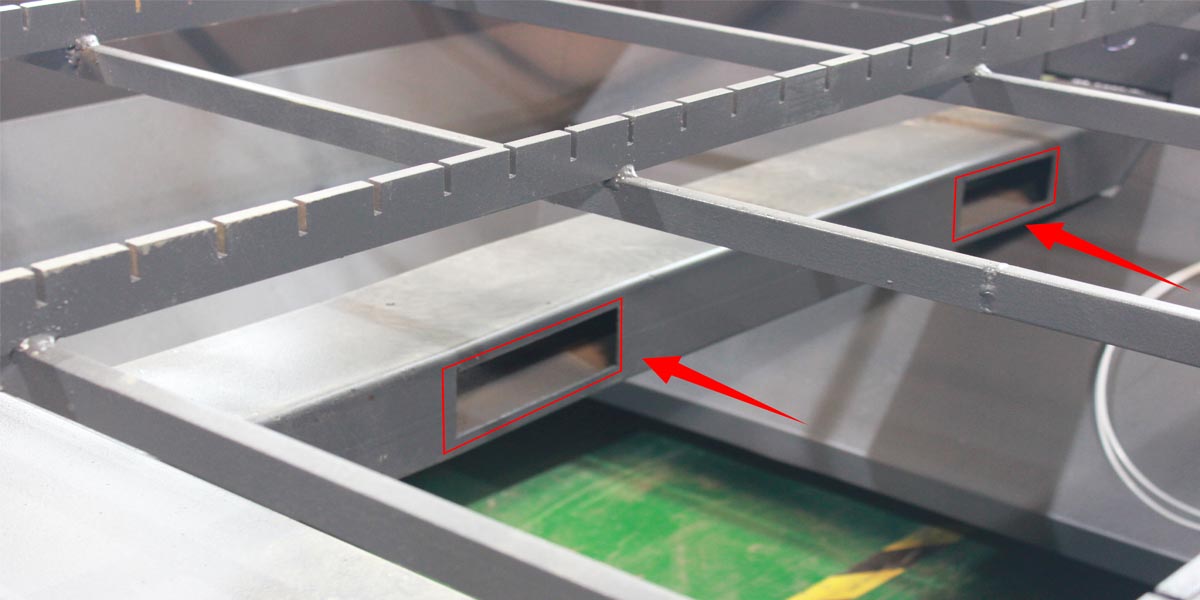

New divided-area dust removing exhaust system can follow machine cutting head to extract the dust and metal particles, more cleaner.

OPTIONS

Video

SAMPLES

![Y10(5VL9]D3ARRJK5E(IBSK](http://www.jinzhaoindustry.com/uploads/Y105VL9D3ARRJK5EIBSK1.jpg)